Someone once told me that writing an article about a Ferrari is rather stupid. Anyone even faintly interested in cars knows about them, people interested a little more will have their pics all over their walls and pc screens; but hardly any of them will be even able to ride it, let alone own it. So who would want to read an article about them? Sounds pretty logical, more so considering no one in my circle of influence is privileged enough to own one (well I don’t think that by me not buying a Reliance phone/fuel it’ll influence Mr. Ambani). But still, there was something about this car, the Ferrari 599GTB Fiorano, that compelled me to write about it.

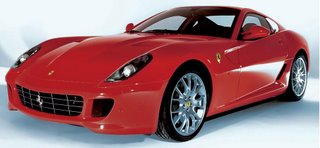

Personally, I consider this recently launched Ferrari to be one of the most visually appealing design penned down by Pininfarina for the Maranello based company. I’ll put it right up there with a 250GT in my list of all time gorgeous looking Ferraris. Well while this point may be debatable, what is certainly not debatable, is the mechanical superiority of the car. Infact it is already being hailed as the best V12 Ferrari ever.

If I start writing about all its features, this article will become far too beg, so instead I’ll restrict myself to the main modifications which stand out. Officially, the replacement of the 575M, the car borrows its 65 degree, 5999cc V12 engine from the Enzo. The engine though is thoroughly reworked and detuned for greater reliability and fuel efficience (read that as more miles before you hit the workshop for engine repairs). This has come at a cost of 6% loss of power, which still at a staggering 612bhp is more than enough to take you to heaven (both in the literal sense and as a sense of euphoria). Ferrari took it mid way in the body deparment, making it entirely of aluminium (575M was steel, while the exclusive Enzo was carbon fibre). All this boils down to a 0-100 kmph sprint time of 3.7 sec and a top speed in excess of 330 kmph. Mindblowing! The car also produces a phenomenal 160kg of downforce (more than 10% of its own weight) after crossing 300 ks. But what is more significant is that the designers have achieved all this without any spoilers or ugly aerodynamic part protruding out (to aid airflow but spoil the curves of the car in the process), instead this has been achieved by a carefully contrived undertray giving a superb coefficient of drag, which is 0.34.

Now, for what probably is the most significant aspect of this car. Ferrari’s traditional double wishbones at each corner now carry magneto rheological (MR) dampers, a technology that a very few manufacturers can boast of (the recently launched Audi TT is one of the very few). Rheological fluids change viscosity in response to an applied electric field (electro-rheological), or magnetic field (magneto-rheological) as in the case of the Ferrari. The magnetic field is varied by electromagnets coiled around each damper. Ferrari says that the MR dampers react in 10milliseconds when the control information that determines the coil current required for each damper is updated every millisecond. Compare it to the earlier mechanical system where control information was updated every 10millisecond and the dampers took upto 4 times as long to deliver the required damping force.

Ferrari is yet to confirm the pricing on the 599, but a tag of Rs. 1,28,00,000 (excluding duties) is expected. But hold, just having the required green bucks won’t guarantee this beauty in your garage, as you have to convince Ferrari first that you status befits the car. In that case I think it is better for people like me, who cannot own it and so I won’t have to face the ignominy to be refused by the company even though I have the money. But certainly I don’t require Ferrari’s permission to buy a poster of it (or in our net savvy age, ‘to download a wallpaper of it’ will be more apt), or even write an article about it!!!